Why Choose US

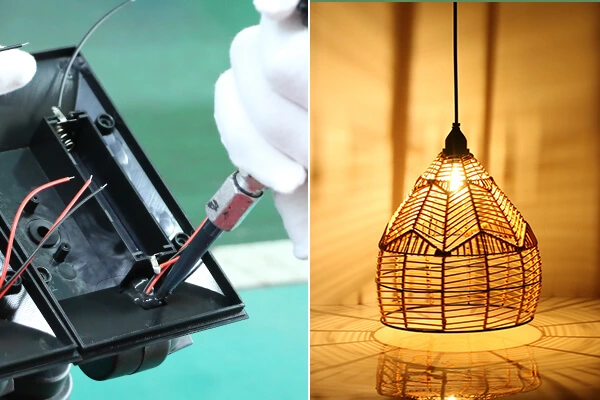

Our quality is reflected in every process and detail of solar light production.

Yinghao Solar Lighting's Quality Control (QC) framework is integral to crafting our dependable solar lighting solutions. This article will outline the critical QC steps we implement to ensure product reliability. From the vigilant selection of raw materials to the rigorous enforcement of manufacturing protocols, our process is streamlined for excellence. Up next, we detail these procedures, underscoring the precision and care embedded in our manufacturing journey, designed to build lasting trust with our customers.

Yinghao Solar Lighting's precision in material selection and process control is a cornerstone of our quality commitment. We meticulously evaluate each material for its durability and efficacy to ensure our solar lighting products stand up to rigorous use. Adhering to the robust ISO 9001 quality management standards, we conduct extensive testing and validation to maintain consistency and reliability. This careful curation of materials and detailed attention to our manufacturing processes establish a strong foundation for producing professional-grade, dependable solar lighting solutions.

In Yinghao, we emphasize the nuanced roles of Quality Assurance (QA) and Quality Control (QC). QA is our strategy for preventing issues by systematizing the production process. It's about setting high standards and ensuring all manufacturing activities consistently align with these benchmarks. In contrast, QC is our commitment to inspecting and testing our solar products. This stage is crucial for identifying and addressing any deviations from our quality standards. Together, QA and QC form a comprehensive approach, ensuring each solar light we produce meets the highest quality and reliability standards.

In solar lighting manufacturing, Yinghao's commitment to quality and continuous improvement stands as a testament to their dedication to excellence. A real-life example that epitomizes this commitment involves the solar garden light model YH1015.

During a routine quality check by a client, an issue was discovered with the YH1015 model(Customized products): the nuts wouldn't properly fit onto the screws. Yinghao's immediate response showcased their proactive and professional approach to quality control. An urgent re-inspection of their inventory revealed no similar issues, indicating this was an isolated incident.

Further investigation pinpointed the root cause: an error in the Bill of Materials (BOM) during system updates, where a nut of the same size but with a different thread pattern was mistakenly used. This oversight led to the mismatch during assembly. Yinghao's Quality Department promptly issued an 8D corrective action report, addressing this error comprehensively to prevent any recurrence.

The high-level leadership at Yinghao, including the Quality Manager and Production Manager, have reinforced their commitment to quality and precision. They stress the importance of meticulous attention to detail in every aspect of the manufacturing process, from material selection to final assembly,It's all in the details.

The client affected by this incident acknowledged Yinghao's professionalism and speed in addressing the issue. Such recognition from customers not only underscores Yinghao's responsiveness but also their dedication to customer satisfaction.

In response to this incident, Yinghao has implemented additional checks and balances in their quality control processes. Regular training sessions for staff on the latest quality control techniques and a more rigorous auditing system for BOMs ensure that such discrepancies are caught and rectified early.

The tale of the YH1015 solar garden light is more than an incident; it's a stark reminder that in the world of manufacturing, success hinges on the smallest details. Yinghao's swift response and thorough analysis of this challenge underscore their deep-rooted belief: excellence lies in the minutiae. This episode not only resolved a potential issue but also strengthened Yinghao's resolve to continuously refine their focus on the fine points of production – because, at Yinghao, they know that the difference between good and great is found in the details.

As we conclude our exploration of Yinghao Solar Lighting's comprehensive approach to Quality Control (QC), it's clear that yinghao commitment extends beyond standard processes and protocols. With precision in material selection, steadfast adherence to ISO 9001 standards, and a clear distinction between Quality Assurance (QA) and Quality Control (QC), Yinghao has established a solid foundation for manufacturing superior solar lighting products. The incident involving the YH1015 model highlights their relentless pursuit of excellence, showcasing how attention to the smallest details can create a significant impact. This ethos of continuous improvement and customer-focused responsiveness firmly positions Yinghao Solar Lighting as a leader in the industry, dedicated to delivering products that are not only reliable but exemplary.

For more information or personalized assistance, please feel free to contact us.

We are available from Monday to Friday

8:30-18:00

YINGHAO

Street: Liande 69

City: Guangdong Province, Zhongshan

ZIP code: 528414

Country: China

This website uses anonymous performance cookies to ensure you get the best experience on our website. We never use targeting or advertising cookies.

Please click here to view our cookie policy.